BIRPLAST promotes circularity in the plastics value chain

The BIRPLAST project, dedicated to obtaining circular raw materials from plastic waste by applying intelligent separation and chemical recycling technologies, has come to an end

This year saw the completion of the BIRPLAST project, in which GAIKER participated alongside three other agents from the Basque Science, Technology and Innovation Network. This research, led by the Sener engineering and technology group, has brought together ten companies to carry out R&D into new technologies for the separation and chemical recycling of plastic waste to ensure the production of high-quality circular raw materials.

BIRPLAST was launched in 2022 with the aim of generating a knowledge base for the development of improved recycling processes in the eco-industry for various complex plastic wastes – mainly generated during the treatment of other waste, such as light packaging, end-of-life vehicles (ELVs) or waste electrical and electronic equipment (WEEE)—as these are resources and raw materials that current state-of-the-art technology does not allow to be exploited to their full potential.

The project has been completed with significant results in terms of advanced separation. In the case of light packaging waste, an improved material sorting stage has been defined to adapt the composition of plastic fractions with limited recyclability and rejects, supported by the application of spectroscopic techniques and data analysis based on machine learning. Work has also been done on the use of plastic waste with some metal residues from car shredders using intelligent separation techniques.

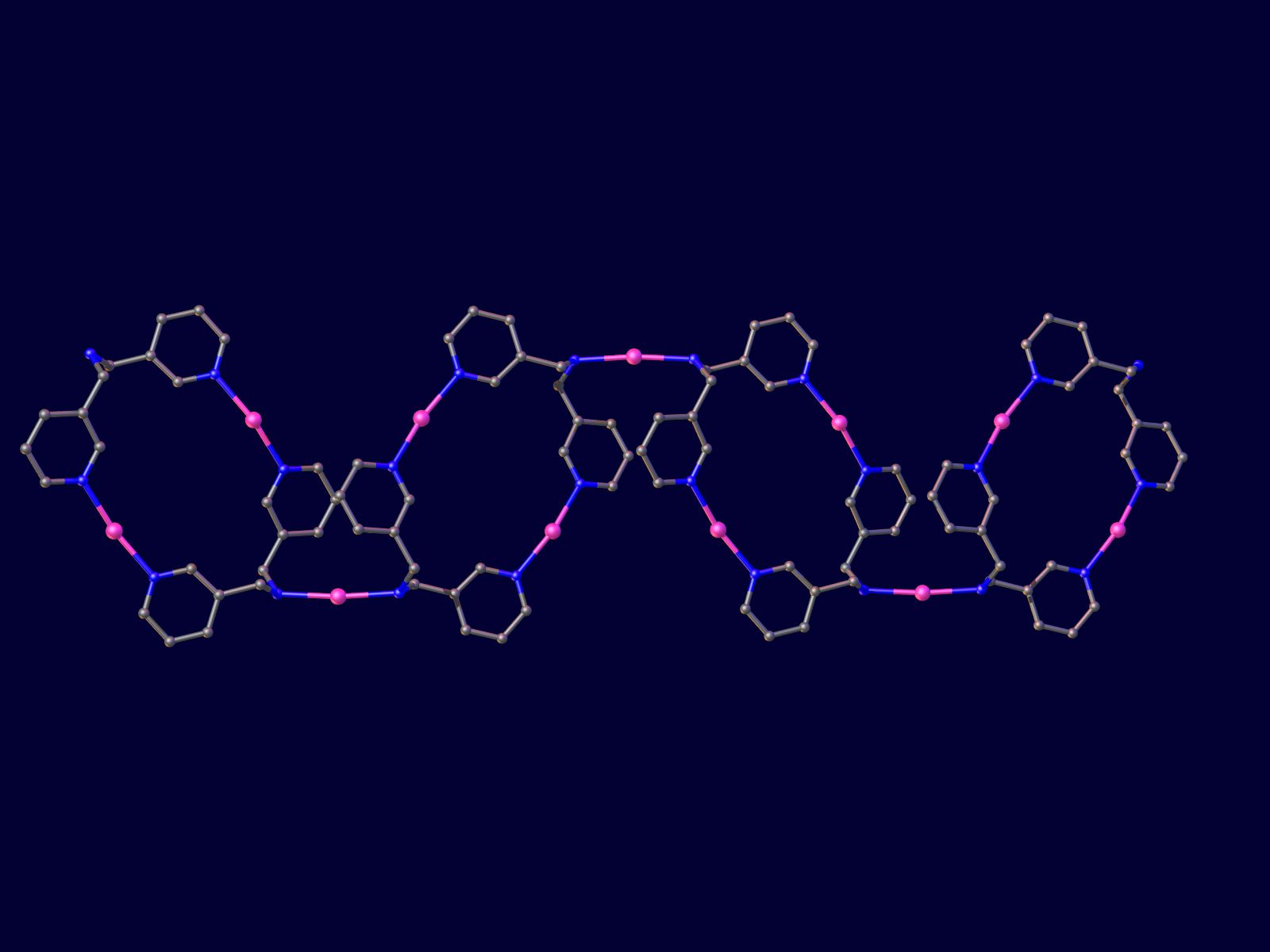

In terms of chemical recycling of waste, new pyrolysis processes have been developed. One of these is for treating mixed plastics, in which the waxes generated are reprocessed to produce lighter and more valuable products while reducing their chlorine content. The other is for processing plastics with biomass to obtain oils with low halogen content. Similarly, new solvolysis processes have been developed to recycle polyesters and polyurethane foams originating from car shredding. Gasification processes have also been adapted to work with different types of waste and varying degrees of moisture, using fluidised bed reactors and jet spouted bed reactors to obtain and purify synthesis gas. Finally, as a complementary measure, treatments have been defined for the water generated during the pyrolysis and gasification processes and the use of pyrolysis oils as wood preservatives.

In addition, for each result, such as intelligent separation processes or monomers, chemicals or oils obtained by solvolysis and pyrolysis, the production efficiency and contribution to the circular economy have been measured, and an environmental assessment has been completed to determine the improvement achieved by generating these circular raw materials compared to the current management of unused plastic waste.