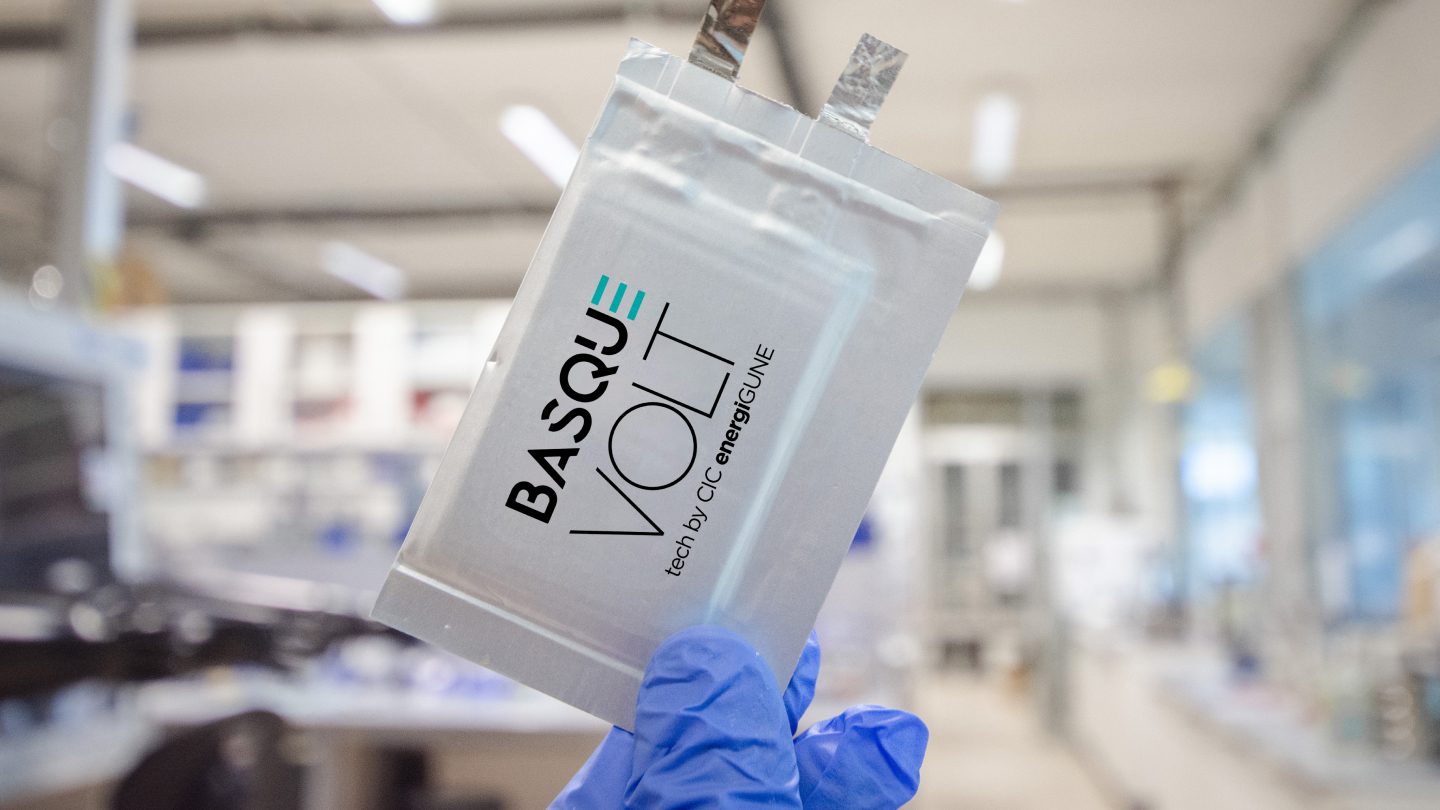

CIDETEC leads an initiative to design Europe’s gigafactories

It brings together the main European players in the sector in San Sebastian to define the bases for independent, efficient and sustainable production of electrodes and battery cells.

The EU’s battery cell production capacity will need to increase from the current 60 GWh to 900 GWh to meet the 2030 targets. This means that Europe needs to efficiently consolidate a large-scale battery cell manufacturing value chain that enables a sustainable and green transition, minimises associated emissions, optimises battery performance and cost, and ensures circularity.

The EU’s battery cell production capacity will need to increase from the current 60 GWh to 900 GWh to meet the 2030 targets. This means that Europe needs to efficiently consolidate a large-scale battery cell manufacturing value chain that enables a sustainable and green transition, minimises associated emissions, optimises battery performance and cost, and ensures circularity.

The European GIGABAT project, led by CIDETEC Energy Storage, was created to address these challenges, with a two-fold focus:

On the one hand, to promote the EU machinery and suppliers needed to gain technological and industrial independence. That is to say, machinery developed and built entirely in Europe that allows us to achieve a leading position in production and efficient use of resources.

In the development of this type of machinery, the aim is to minimise energy consumption, eliminate air and water pollution and integrate intelligent control processes to minimise waste, thus reducing costs and environmental impact. In addition, it is expected that such machinery will operate at very high productivity levels with intelligent quality control systems incorporated based on Industry 4.0 strategies.

On the other hand, the project will promote collaboration between industrial-scale cell manufacturers, battery processing equipment companies, material suppliers and grid energy providers, all implementing sustainability and efficiency standards in the flow of materials and energy along the production chain. Some of the topics to be investigated will be the environmental impact of different machinery, production line configurations and factory layouts in order to come up with best practice proposals.

The GIGABAT project, funded by the Horizon Europe programme of the European Commission, aims to strengthen the EU cell manufacturing industry and its value chain, and to involve its key stakeholders in the development of GEN3b (Li-ion) batteries. The project is composed of : PowerCo SE (Volkswagen Group’s battery manufacturing subsidiary), Verkor, Manz Italy, Braunschweig Technical University, Izertis, Comau, Heraeus Noblelight, Matthews International, Jagenberg, RISE, Ferroglobe Innovation, Zeppeling Silos, Netzsch Trockenmahltechnik, ICOS and the European association of LiPLANET battery pilot plants, of which CIDETEC is also a member.