GAIKER bets on additive manufacturing to optimise the thermoforming of ESD materials in a project in collaboration with Ikor Technology Centre and TECNUN

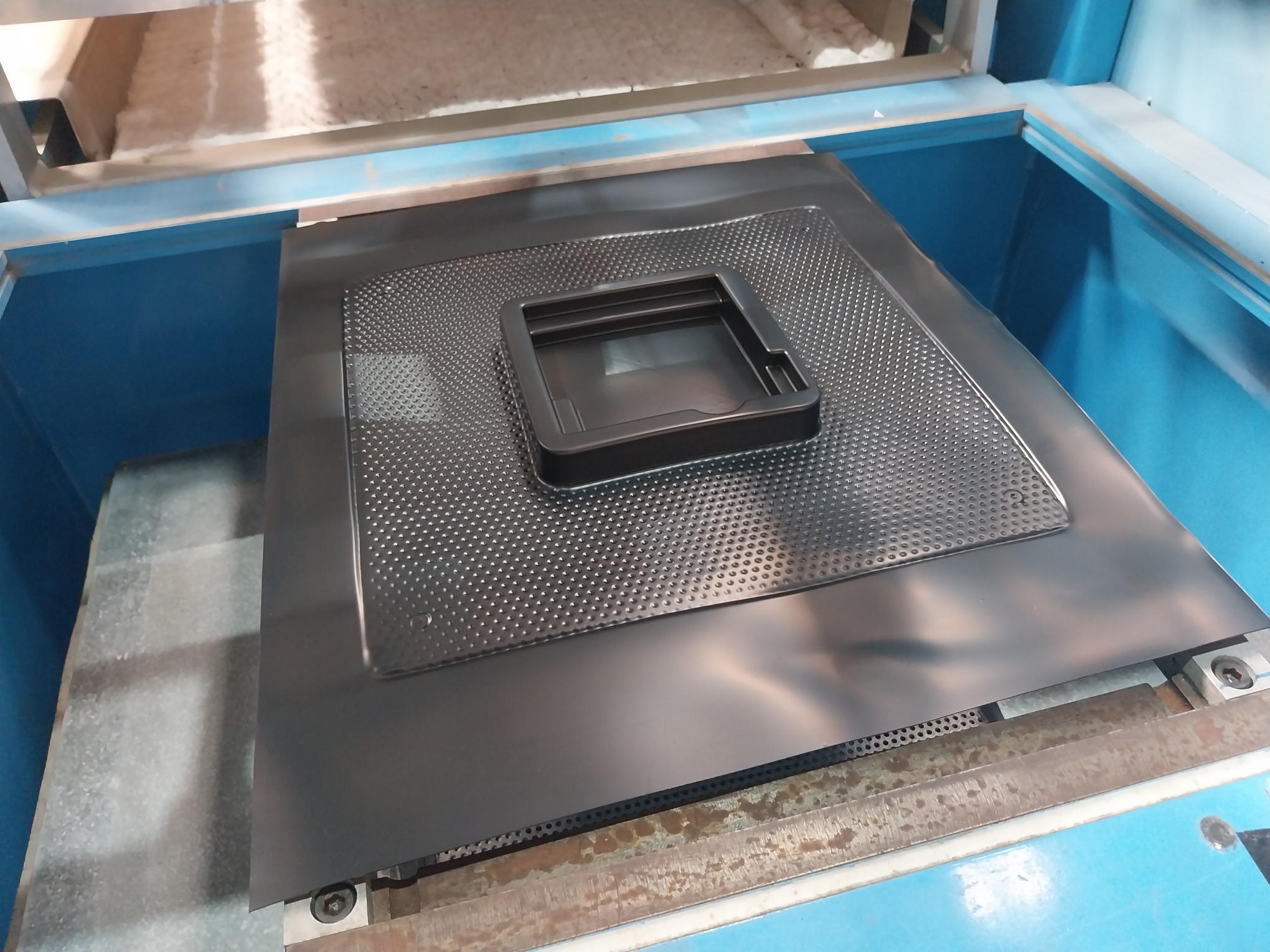

The ECOLAJE project explores the advantages of using additive manufacturing to make moulds for thermoforming ESD materials and investigates recycling strategies for ESD trays made with these moulds.

The GAIKER Technology Centre, a member of the Basque Research & Technology Alliance, BRTA, is participating in the ECOLAJE project whose main objective is to optimise the thermoforming of ESD packaging, using moulds made by additive manufacturing in combination with various recycling strategies, as well as the use of post-industrial and/or post-consumer material.

In a project to produce containers or packaging using the thermoforming technique, but gaining in speed and flexibility, it is very useful to produce the moulds using additive manufacturing. This technology allows the integration of additional features in the moulds, such as cooling channels and surface textures, which improves the quality of the parts produced and reduces production cycle times.

The ECOLAJE project seeks to explore the benefits of using additive manufacturing to make thermoforming moulds for ESD materials, so that they can be used in the manufacture of trays for transporting electronic products and do not suffer any electrostatic discharge during handling and transport, thus avoiding damage to electronic circuits. In the same way, the aim is to promote the circular economy by researching, on the one hand, into different strategies for recycling ESD packaging and, on the other, into the manufacture of these trays from recycled and post-consumer materials.

This research is carried out in different phases: firstly, a complete study of FDM materials is carried out and the most suitable materials are selected for the production of the moulds. Subsequently, the requirements of the parts to be thermoformed are determined in order to define a verification procedure and study their deterioration. In the following phases, research is carried out on the design and development of moulds for thermoforming by means of additive manufacturing and their validation, as well as on how to improve the sustainability of this process, proposing different recycling strategies for ESD trays and analysing the functional deterioration of thermoformed parts, especially the loss of ESD properties (loss of surface resistivity).

GAIKER is mainly involved in the latter activities, leading the work package ‘Recyclability strategies of ESD materials in thermoformed parts’, where the research of different recycling strategies is proposed and the variation suffered by the ESD properties of the manufactured packaging is studied in each one of them. The aim is to evaluate the best strategy for optimising recycling cycles while maintaining functional properties (anti-staticity).

This project, financed by the Basque Government as part of its programme of aid for collaborative research in strategic areas, ELKARTEK 2023, involves, in addition to GAIKER, an expert in the development, processing and characterisation of plastic compounds and in recycling and circular economy, IKOR Technology Centre, S.L. (project leader) and the School of Engineering of the University of Navarra, TECNUN.