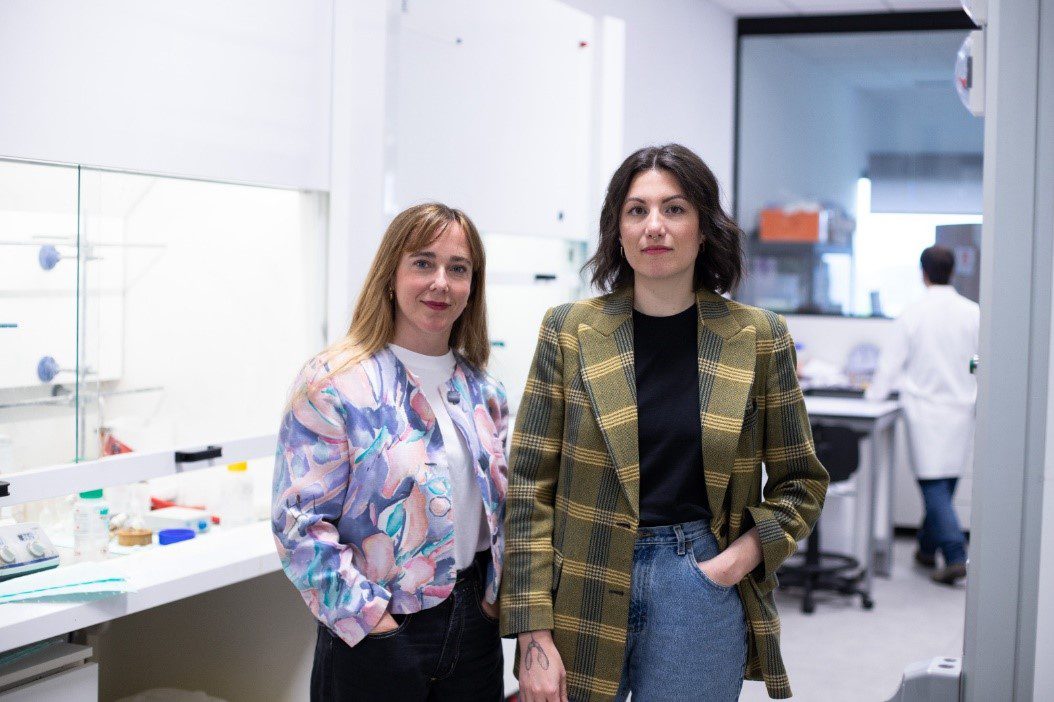

GAIKER develops new technologies for non-contact monitoring of composite materials

The MOSINCO project will improve the way composite parts are manufactured and maintained, allowing for greater control over quality, safety and traceability.

The GAIKER technology centre is leading the MOSINCO project, whose main objective is to develop new technologies that enable contactless monitoring of composite materials, covering everything from the manufacturing process to the end of their useful life. Its purpose is to guarantee the quality, safety and traceability of the parts, reducing defects, maintenance costs and waste.

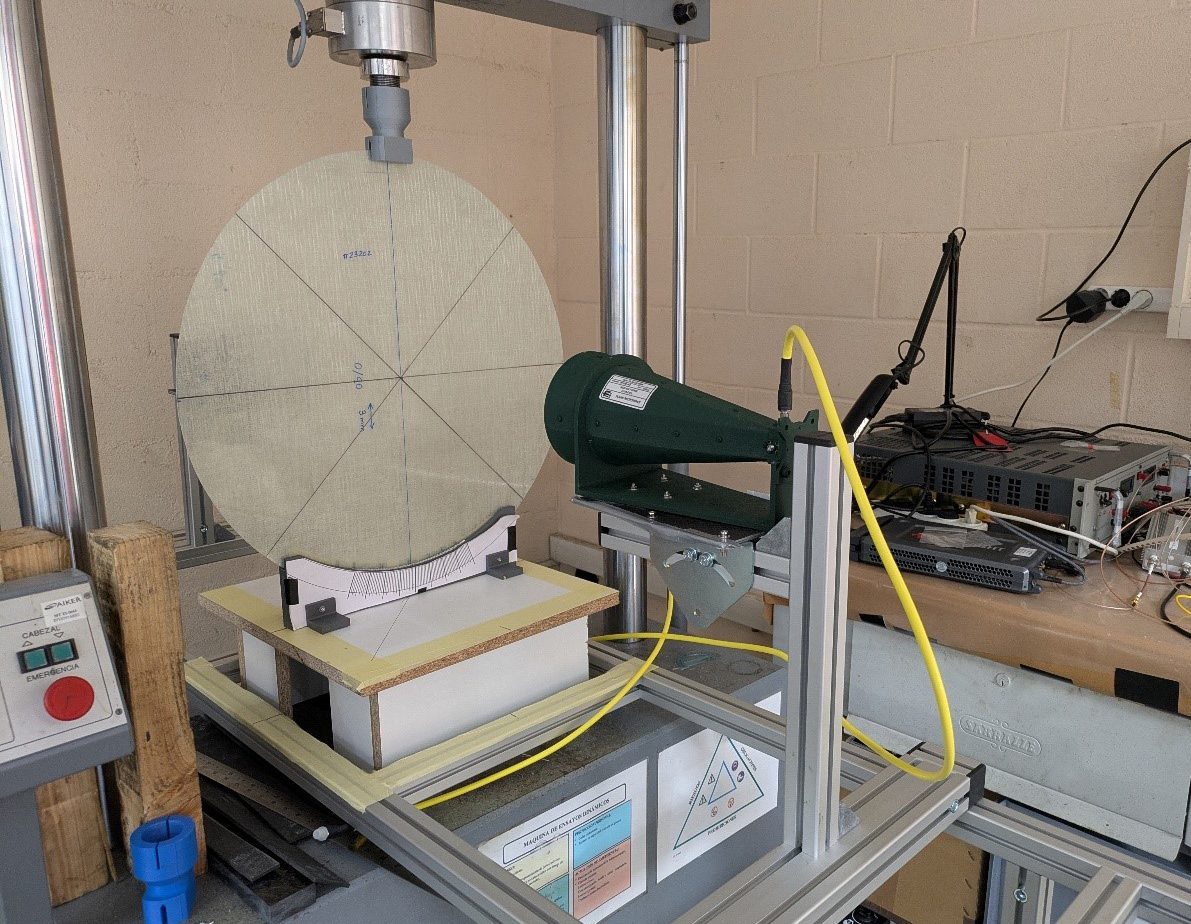

This research aims to open the door to a new generation of smart composites with self-diagnostic capabilities and optimise their maintenance, avoiding routine and costly inspections. The aim is to improve manufacturing efficiency and the structural properties of parts, using less material. To achieve this, work is being done on the development and integration of three technological lines. Firstly, magnetic micro-wires embedded in the materials that allow the detection of deformations, stresses and strains or temperature changes. Secondly, air-coupled ultrasound (ACA) to detect defects and evaluate the curing of the material during its manufacture. And finally, functional inks, which change colour with temperature and allow the curing process to be controlled or each part to be uniquely identified. The potential of these three technologies is analysed in the project both individually and by identifying the possible synergies that may arise between them.