GELECTRODE: a project set to revolutionise selective aluminium anodising

CIDETEC Surface Engineering will contribute its expertise in surface treatments to develop GELECTRODE technology

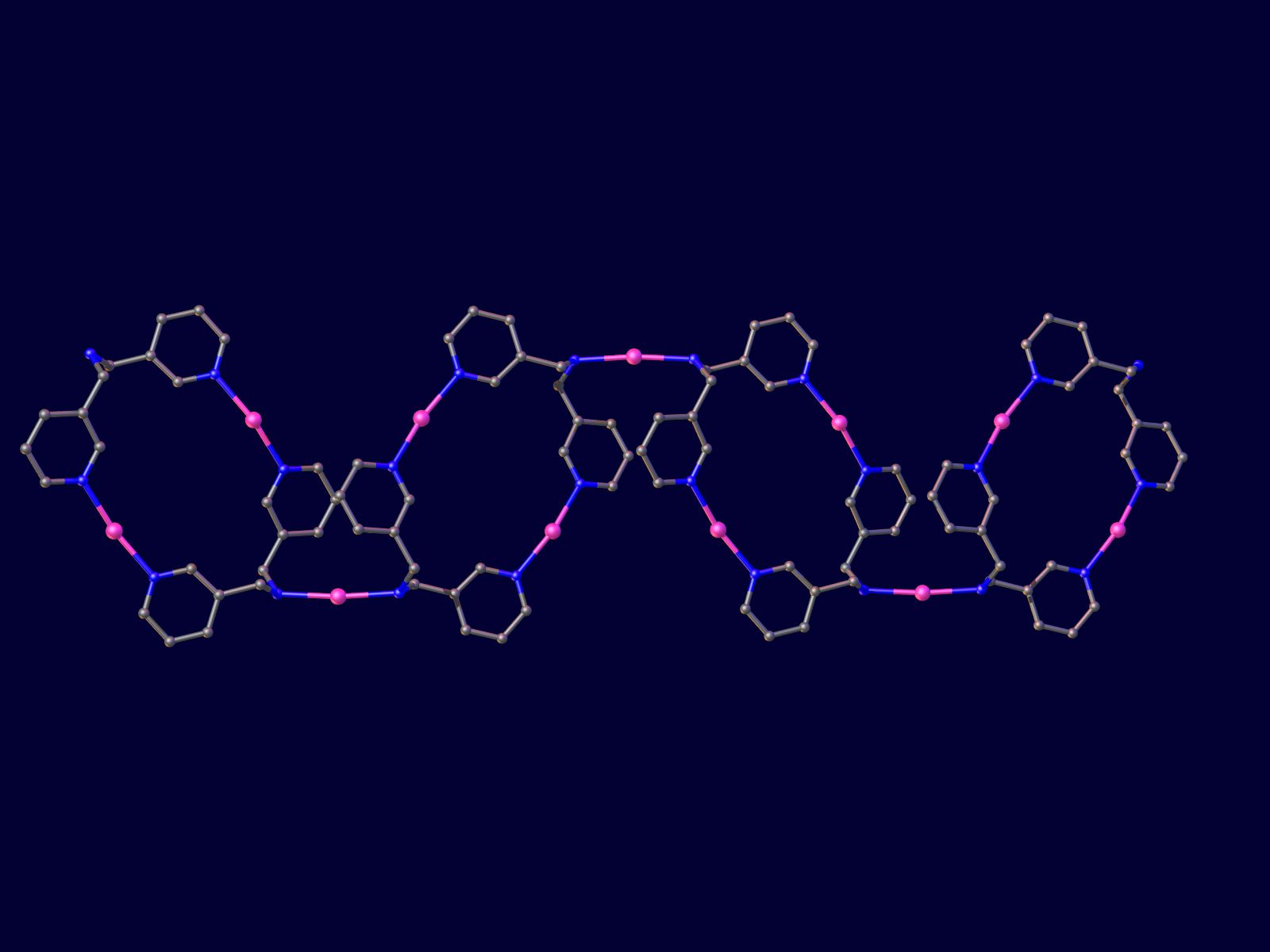

The Eurostars GELECTRODE project: A self-standing gel-electrode device for local anodising, has been launched with the aim of transforming selective treatments on aluminium surfaces through the development of a flexible, self-supporting device based on gel electrolytes. This innovative solution will enable localised anodising without the use of corrosive liquid electrolytes, overcoming the limitations of current systems and improving safety, efficiency and sustainability in maintenance and repair operations (MRO). The technology will cover processes such as SAA (Sulfuric Acid Anodising), TSA (Tartaric Sulfuric Acid Anodising) and PAA (Phosphoric Acid Anodising), significantly simplifying repair tasks and reducing risks and environmental impact.

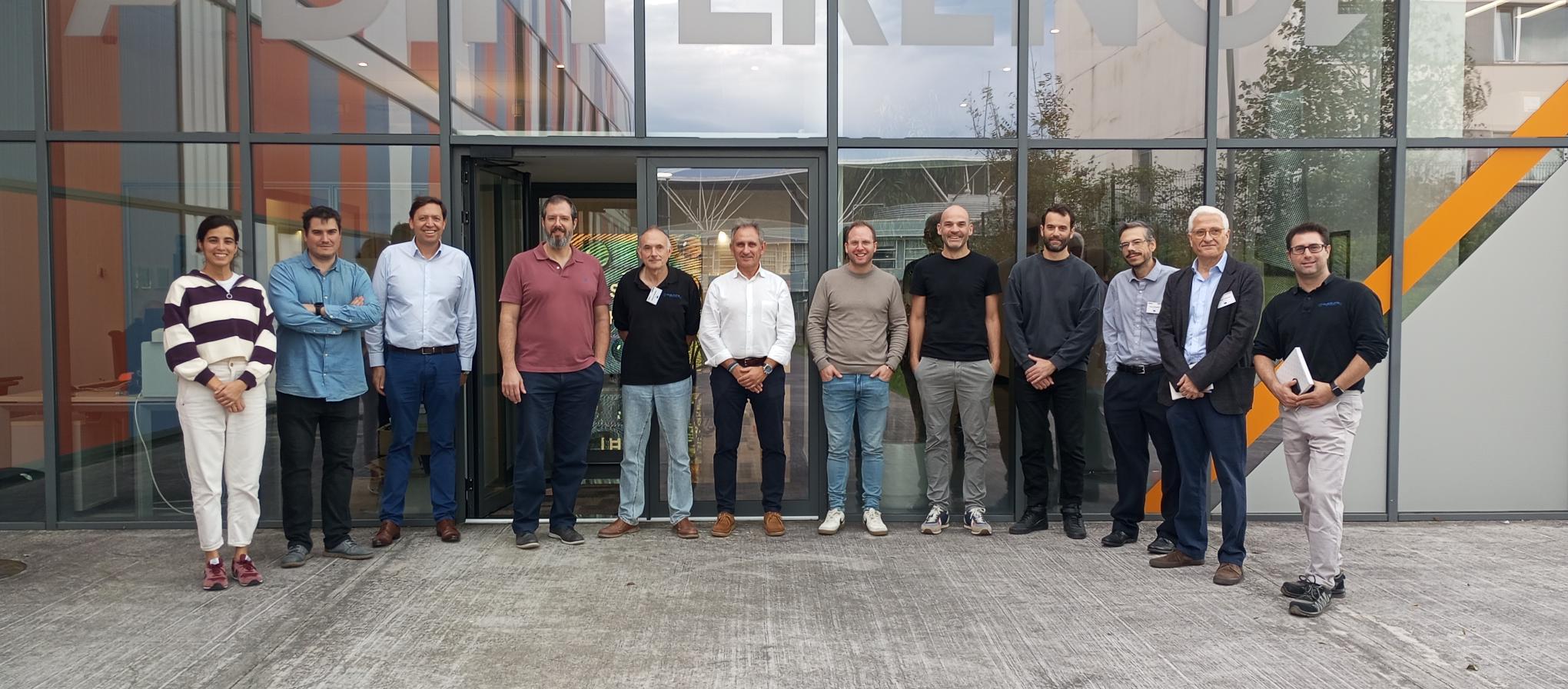

With a budget of €2,518,000 and an implementation period running from November 2025 to April 2028, GELECTRODE brings together a consortium of leading companies in their respective fields. Chemplate Materials SL will be responsible for manufacturing and process optimisation, Talento Corporativo will provide predictive algorithms, Principia Ingenieros Consultores will develop thermal simulation models, GMI AERO will design the portable kit consisting of a power supply, monitoring sensors and auxiliary elements, and ACRATS will validate the technology in real aeronautical environments.

CIDETEC Surface Engineering will play a central role as the technology developer. Its participation will cover the original formulation of the gel and the definition of the application processes, monitoring to feed algorithms and thermal models, support in the design of the portable kit, and collaboration in the validation phase in MRO environments. With GELECTRODE, CIDETEC reaffirms its commitment to sustainable innovation and continuous improvement in surface treatments for the aeronautical industry.