Lantek launches v44: The next level of connectivity, real-time information and smart manufacturing

An enhanced version designed to revolutionise manufacturing processes under the ‘Connected. Live. Smart.’

Lantek, a global leader in software solutions for the metal sector, presents the latest update of its v44 software, an enhanced version that redefines manufacturing processes under the concept ‘Connected. Live. Smart. This update encompasses a full suite of innovations in its CAD/CAM, MES and ERP software, aimed at maximising production efficiency, connectivity and decision making.

With this latest update, manufacturers gain unprecedented control of their production environments, leveraging new capabilities that integrate machines, streamline workflows and improve data-driven analytics. All of this is a breakthrough for companies looking to optimise their operations with cutting-edge technology.

Lantek Expert 2D CAD/CAM

v44 brings significant enhancements to optimise 2D CAD/CAM workflows. Among its main new features is Property-Based Nesting, which allows parts to be grouped according to attributes such as delivery date, customer or other data, thus improving efficiency throughout the production process. This capability not only organises parts for better packaging and assembly, but also offers the flexibility to separate or combine groups with the option to insert separator lines to facilitate cutting. The new Import Wizard allows filtering layers in DXF/DWG files, as well as removing unnecessary geometry during file import, significantly reducing manual clean-up and speeding up the preparation phase. In addition, the Punch Swap function in the Turret Configuration solves the challenge of turret limitations by allowing the use of rectangular and square punches in operations performed with different sized punches, even when loaded at different angles, ensuring smoother operations without complicated workarounds.

Lantek Flex3D 3D CAD/CAM

With version v44, users will experience improvements in performance, usability and productivity for tube and profile cutting. The process of importing parts has been re-engineered, as well as the management and saving of jobs, which offers a faster response time for the system, improving agility in its use. In the manufacture of structural parts, the new part division techniques allow the selection of divisions in Straight, Angle or Z-shape modes, integrating weld preparations and spaces that guarantee dimensional accuracy after welding. In addition, compatibility with robotic cutting heads extends Flex3D’s capabilities to machines with more than five axes, optimising cutting paths for complex structural steelwork projects.

Lantek MES

v44 introduces improvements that significantly increase efficiency and flexibility on the shop floor. The new Lantek MES Intralogistics optimises the flow of materials from the warehouse to the work centres, reducing downtime and ensuring the availability of materials on the cutting machines. This improvement also increases traceability and minimises errors, resulting in more efficient operations. The new 3D Finishing feature allows completed parts to be recorded directly into the system without the need for complex graphic nesting, simplifying waste management. In addition, advanced management of lost parts allows operators to resume work from the exact point where the problem arose, avoiding complete restarts and significantly reducing delays.

Lantek Integra ERP

This version 44 improves usability and accuracy in cost management, streamlining workflows. The new Drag & Drop function facilitates file management, allowing users to quickly add geometry files or documents in areas such as Sales Orders or Tracking Numbers, with automatic file type recognition. This simplifies the process, making it easy to manage even for less experienced users. In addition, the definition of the price of scrap material gives more precise control over costing by allowing specific prices to be defined for each type of material, ensuring more competitive and accurate quotes with full traceability.

Bending

Lantek Bend v44 introduces features designed to improve automation and integration in bending processes. The Enhanced CAD Import Module allows the import of formats from the latest native CAD systems, with automatic recognition of materials, thicknesses and bend lines. The new Starmatik export function allows bending line data to be exported in DXF format for robotic programming, ensuring optimum accuracy. In addition, Integration with Lantek Expert, MES and Integra makes Lantek Bend a fully connected solution, allowing the opening, modification and synchronisation of 3D files across all systems, improving efficiency in data management and production.

A step further in intelligent manufacturing

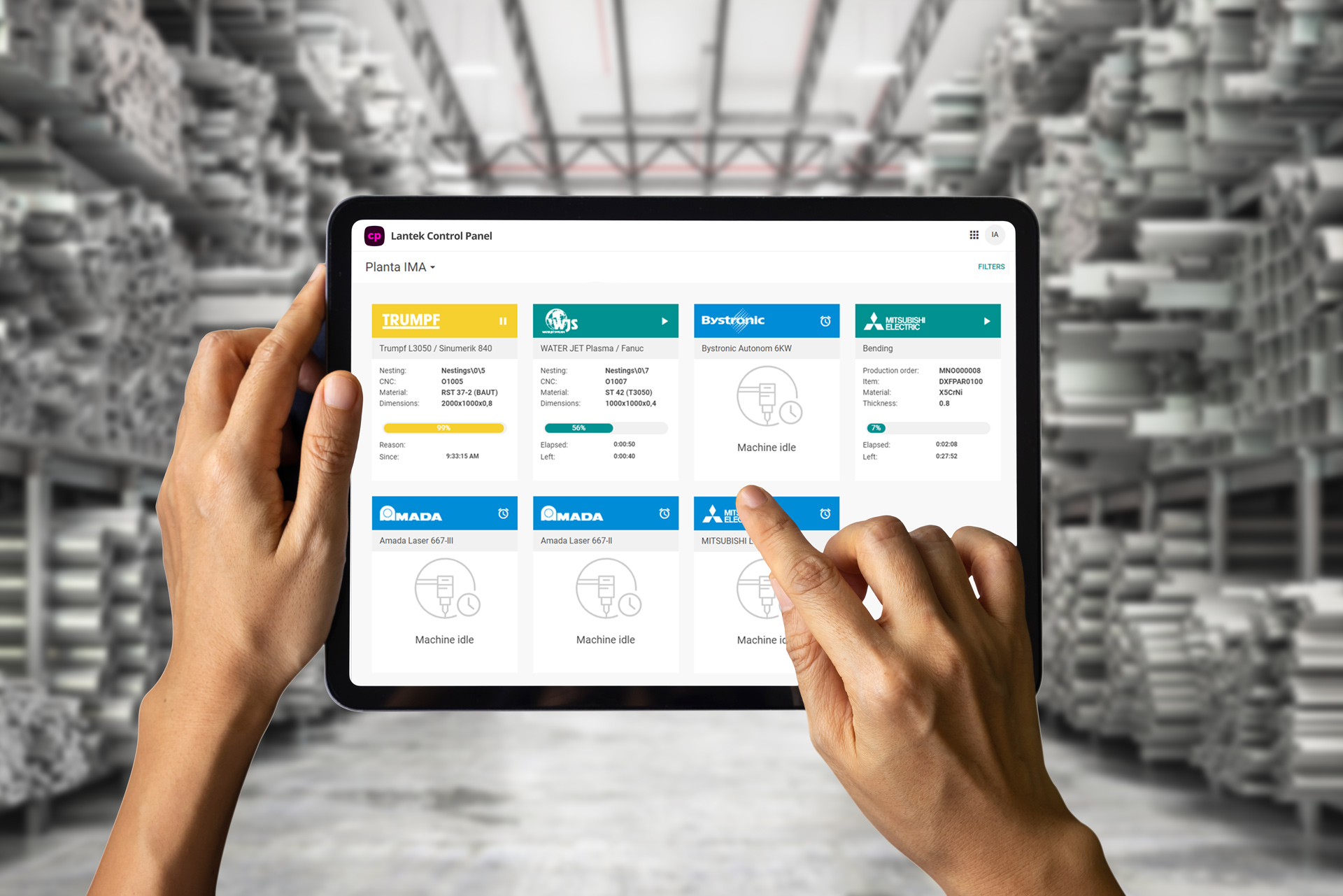

Lantek v44 is not just a software update; it redefines how modern manufacturing should work. The new concept ‘Connected. Live. Smart.’ concept, together with Lantek Analytics, provides manufacturers with real-time information and smarter decision making by connecting machines, operators and data sources. This powerful tool improves production efficiency, allowing users to optimise planning, monitor performance and gain complete visibility of their production lines.

‘Our goal with this latest v44 update is to empower factories to become more connected, more efficient and smarter,’ says Raúl Chopitea, Product Manager at Lantek.