Lantek participates in Industry LIVE 2025 with its wide range of technological solutions for the sheet metal industry

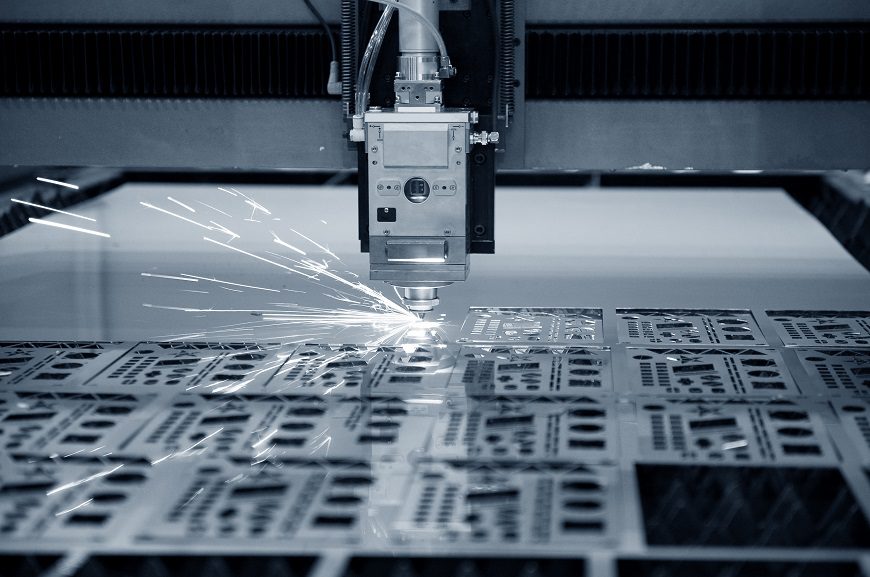

It will showcase its v44 suite, designed to radically transform the way sheet metal manufacturers operate by incorporating significant improvements in connectivity, data flow, and decision-making.

Lantek, a multinational company based in Álava and a pioneer in the digital transformation of the sheet metal and metal cutting and processing sector, has announced its presence at Industry LIVE 2025, which will be held in Hall 8 of IFEMA (Madrid) on 18 and 19 June.

At this second edition of the fair, the company will showcase its wide range of advanced solutions and new manufacturing features, as well as the latest versions of its software solutions, aimed at all types of companies in the sheet metal sector.

“With our presence at Industry LIVE, we continue to show the industrial world everything our solutions can contribute to the production efficiency of the digital factory, taking connectivity between machines to a new level. With the concept “Connected. Live. Smart.”, we are redefining manufacturing processes to help companies optimise their operations and make more informed decisions that drive their growth and profitability strategies,” says Joseba Montoya, Commercial Director at Lantek.

Lantek news: v44, Machine Connectivity and Assembly to Nesting

Lantek v44, the latest version of the manufacturer’s software suite, and its “Connected. Live. Smart” approach focused on redefining production efficiency in smart factories, will form the basis of Lantek’s presence at Industry LIVE.

This new version improves connectivity, data flow and real-time decision-making, leveraging state-of-the-art tools. Lantek’s suite of solutions offers unprecedented visibility, radically transforming the way sheet metal manufacturers operate.

Among the technological advances that Lantek will showcase during the fair, the integration of Machine Connectivity technology into its software stands out, enabling the reception of real-time data from cutting machines, for any model and manufacturer.

This new technology has led to the launch of two new products: Wos Automático and Control Panel. The former exploits real-time data for precise time control, thereby improving efficiency in production scheduling and job costing. Control Panel shows the status of a workshop in real time, providing manufacturing managers with a complete system for viewing what is happening on each machine or line, at any time and from any device.

In addition, Lantek will showcase the Assembly to Nesting (A2N) functionality, designed to address the growing demand from its customers for more efficient handling of 3D files. A2N is an advanced importer of 3D parts and assemblies that stands out for its ability to automatically unfold sheet metal parts. Its benefits are significant: fast processing of 3D models; elimination of the need for external 3D CAD tools; and total precision in the unfolding of parts, thanks to user-defined rules.

Finally, Lantek will showcase the new features of the Lantek MES and Lantek Integra products with Lantek Flex3D. With all these new features, already incorporated into Lantek v44, the company provides the most flexible tube and profile cutting solution, thereby improving its usability, automation capabilities and integration into the company’s factory management solutions.