Sustainable materials for reducing the environmental impact of industry

The Minerva project has been launched with the aim of developing materials destined to help deal with current social challenges such as generating clean energy, developing electromobility and reducing the impact of industry on the environment.

The initiative, which was launched last July and is ongoing until December 2023, is based on state-of-the-art material transformation technologies, multiscale characterisation and digital tools such as simulation.

The project is headed by Ceit and the consortium comprises Azterlan; UPV/EHU; Mondragon Goi Eskola Politeknikoa S. Coop; TECNALIA; LORTEK; EIPC and Tekniker.

Meeting current needs without comprising future generations has become a common objective. Industry worldwide is involved with sustainability and is experiencing constant changes in terms of advancement in developing more sustainable products that are both efficient and able to deal with current social challenges, such as electromobility, air transport with less environmental impact and the generation of clean energy.

Meeting current needs without comprising future generations has become a common objective. Industry worldwide is involved with sustainability and is experiencing constant changes in terms of advancement in developing more sustainable products that are both efficient and able to deal with current social challenges, such as electromobility, air transport with less environmental impact and the generation of clean energy.

Within this scenario, the Minerva project, funded by the Basque Government and forming part of the ELKARTEK programme framework, has been launched as a response to these problems and to develop state-of-the-art materials with high performance features and multiple characteristics, which may remain sustainable throughout their lifespan. At the same time, other major benefits for industry are guaranteed, such as the efficiency of processes, durability of products, reduction in the cost of production, and the elimination of materials deemed critical to the environment, among others.

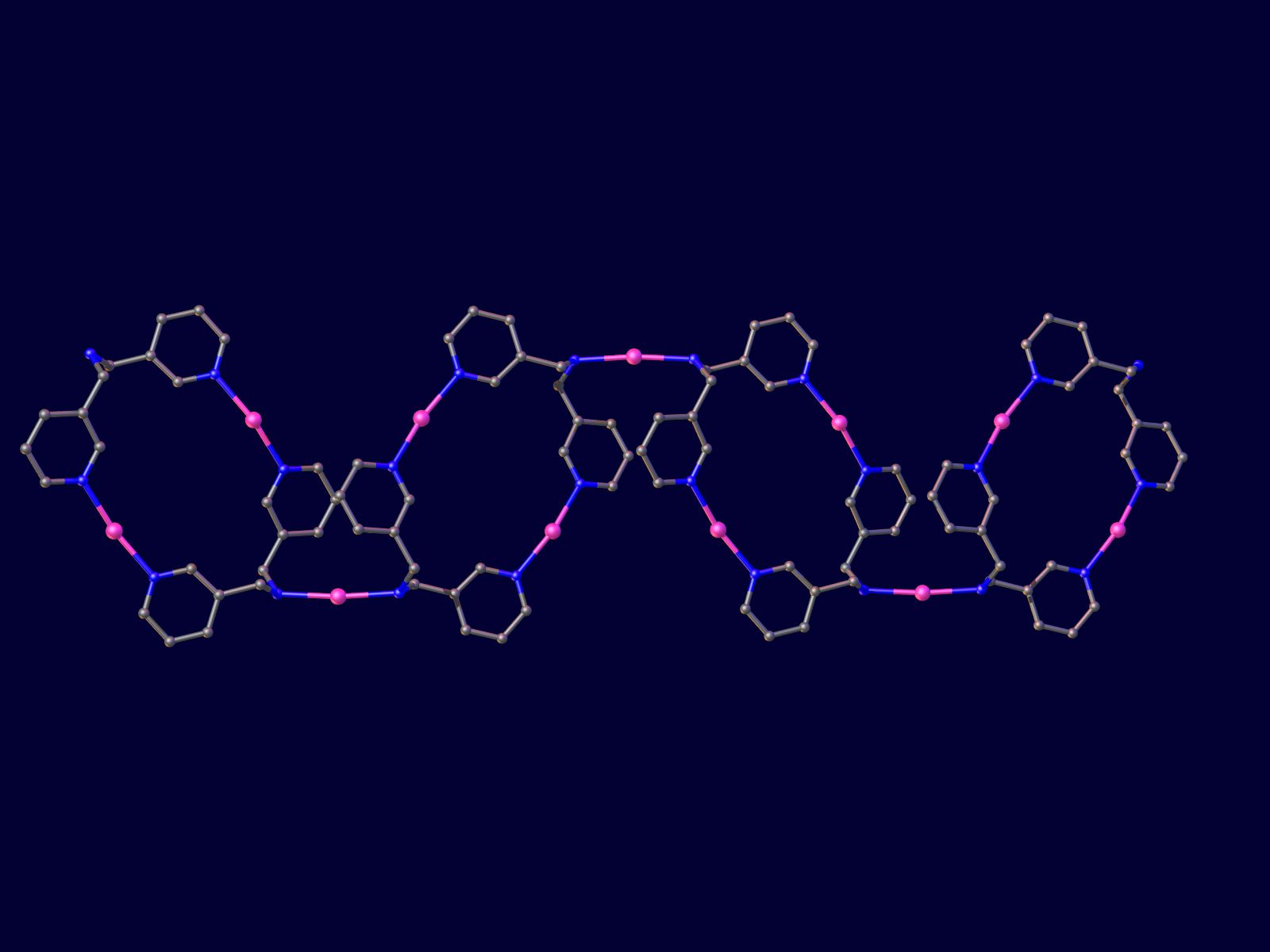

Using already-existing materials, producing new ranges of high-entropy and shape-memory alloys (HEAs and SMAs) is, for example, proposed as part of the initiative, as well as their combination with transformation technologies such as laser welding and additive manufacturing, so as to obtain new functional products. Digital tools, in silico models and multiscale characterisation methodologies will also be developed.

Partners will be combining synergies and additional technological capacities to provide metal and ceramic materials with mechanical, electrical and magnetic properties in order to obtain a triple benefit: covering the most important current needs within the industrial fabric, broadening the characteristics of the materials and creating new market opportunities.

The Minerva project to work in three strategic areas for industrial activity in the Basque Country.

The first of these is smart industry, as advances in automation and improvements in processes, together with the challenge involved in digital transformation and the efficient use of material and energy resources, mean that this project needs to seek out new products and solutions in order to provide added value and improve the competitive positioning of Basque industry.

The commitment to developing cleaner energies constitutes the second pillar. Environmental sustainability and a transition towards a low-carbon Basque economy is sought via the efficient use of materials and their functional validation.

Lastly, attention should be drawn to the contribution made by Minerva to the area of health, pursued via the development of materials that can be used in remote health monitoring, as well as actuators for surgical interventions.

All the above forms part of the technological-digital, energy-environmental and socio-demographic strategies included in the Euskadi 2000 Science, Technology and Innovation Plan (STIP). At the same time, the project is aligned with the missions set out in the Horizon Europe framework programme through transversal driving initiatives involving electric mobility, circular economy and healthy ageing.

Greener materials with better properties

The initiative, which was set in motion last July and will be ongoing until December 2023, constitutes an attempt to take the best possible advantage of materials by providing them with unique properties via the redesign of their composition and microstructure, as well as their compatibility with state-of-the-art transformation technologies, covering critical aspects of the value chain of a product.

By the end of 2023, it is hoped that data pertaining to the entire lifespan of materials will be gathered and assessed, ranging from design until the end of their working life. This will be done via demos that enable new materials geared to the haulage, aeronautical, energy and machine tool sectors to be validated.

Nerea Burgos, project coordinator and researcher from the Advanced Powder Metallurgy and Laser Manufacturing group at Ceit, which is heading the project, explains that Minerva is trying to “tighten the screw a bit more on state-of-the-art materials in order to incorporate other new ones on the market that are more committed to the use of electric vehicles (EVs), air transport with less environmental impact, and the generation of clean energy”.

There will be a dual impact on the industrial fabric of the Basque Country as a result of the initiative as, on the one hand, the diversity of the products it offers will be broadened and, on the other, it will become further established as a leader on the overseas market. Along these lines, Nerea maintains that “Basque companies will manage to establish themselves as leaders on a new European and overseas market which, in turn, will open up new business opportunities”.