Tekniker to test materials for space structures and mechanisms

The Tekniker technology centre has been chosen by the European Space Agency (ESA) and the French National Centre for Space Studies (CNES) to participate in the SESAME test programme. The purpose of the initiative to be carried out at the International Space Station’s (ISS) facilities is to assess the degree to which the space environment affects materials

It is in the low Earth orbit (LEO), at a distance ranging between 200 and 2,000 km above to the Earth, where most of the observation satellites like the Hubble space telescope operated by the International Space Station (ISS) are located. This orbit provides a highly suitable environment to test and monitor how the space environment can affect materials and their use in applications on future space structures and mechanisms.

It is in the low Earth orbit (LEO), at a distance ranging between 200 and 2,000 km above to the Earth, where most of the observation satellites like the Hubble space telescope operated by the International Space Station (ISS) are located. This orbit provides a highly suitable environment to test and monitor how the space environment can affect materials and their use in applications on future space structures and mechanisms.

In this regard, the European Space Agency (ESA) and the French National Centre for Space Studies (CNES) have rolled out the SESAME Euro Material Ageing 2020 test programme for use aboard the Bartolomeo research platform to run tests on the external module to be launched next year and docked to the ISS. The use of materials with a high potential for current and future interstellar missions will also be studied.

The Basque technology Centre, Tekniker, a member of the Basque Research and Technology Alliance (BRTA), has been chosen to participate in this initiative by making available to both European agencies its extensive expertise and in-depth knowledge with regard to tribology and research actions focused on the materials and coatings used in this setting. Tekniker has been selected from among 14 specialised European centres due to its outstanding capabilities in terms of developing materials designed to withstand conditions in outer space.

More specifically, the technology centre will manufacture two samples of materials using diamond-like carbon (DLC) coatings and surfaces treated with Plasma Electrolytic Oxidation (PEO).

The ultimate goal is to test the use of DLC and PEO and to gather representative data to further the development of these materials to be used on future space structures and mechanisms to improve the current state of the art and shorten their application road maps.

Space applications

Tekniker is currently developing carbon-like diamond coatings (DLC) applied by means of Physical Vapour Deposition (PVD) and Plasma Assisted Chemical Vapour Deposition (PACVD) techniques. The ultimate goal is to improve the durability and performance of tribological components in space applications by reducing friction and wear coefficients and improving the tribological response of titanium components.

This coating prevents phenomena such as tribocorrosion in the form of wear produced by mobile contact or cold welds that may occur between similar materials when in contact with each other in vacuum environments.

“DLC is one of the most promising coatings because of how well it can adapt to multiple applications. It also delivers exceptional properties: low friction, extreme hardness and excellent corrosion resistance. This explains why it has a high potential to be used on mobile mechanisms aboard space exploration missions as it operates like a solid lubricant, a most outstanding feature when working under vacuum conditions”, says Borja Pozo, a researcher and coordinator of the space sector at Tekniker.

Tekniker will also contribute its knowledge in the field of Plasma Electrooxidation (PEO) which is an advanced coating technique that forms protective layers on metals to develop wear and corrosion resistance on space structures made of light metals such as aluminium, aluminium-silicon and titanium.

This technique can provide unique properties for materials in the form of higher growth speed, greater thickness, less roughness, more hardness, better corrosion and wear resistance, etc. As the material is black, it is possible to achieve high levels of emissivity and absorbance. In the case of thermal applications, these two properties are a must for certain internal aerospace components.

Materials developed by means of PEO have a high potential to be used on space missions such as Artemis, Mars Sample Return or aboard deep-space missions.

Consequently, Tekniker has until May 2021 to manufacture the two samples requested by ESA and CNES. Subsequently, preliminary tests will be run at the facilities of both organisations until the end of 2021 in order to incorporate both samples in the ISS launch scheduled for the end of 2022.

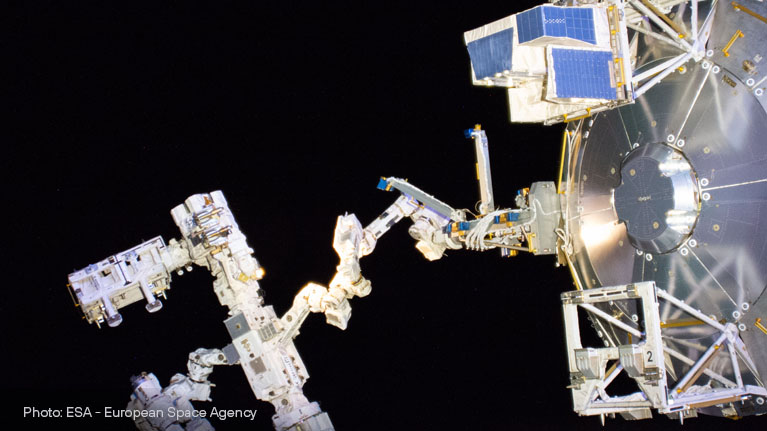

Throughout this process, Tekniker will provide its experience and expertise in terms of research associated with tribology, materials and coatings to assist in the development of space missions such as Mars Sample Return, Gateway or Athena. As the centre also intends to enhance its space technology capabilities, it will soon be possible to deliver more information validated in a real environment and apply coatings quicker on structures used on spaceships and mobile mechanisms in the form of aerials, robotic arms, scientific systems, etc.

The SESAME testing programme, scheduled to return at the end of 2023 for tests to be performed at the ESA and CNES facilities, will assist ongoing and future ESA missions and offer research centres, universities and private companies the opportunity of testing up to 45 materials covering the entire spectrum of the low Earth orbit.