GAIKER has a new pilot plant for the chemical recycling of complex PET waste

This equipment makes it possible to scale up chemical recycling processes to a suitable size between laboratory processes and industrial plants.

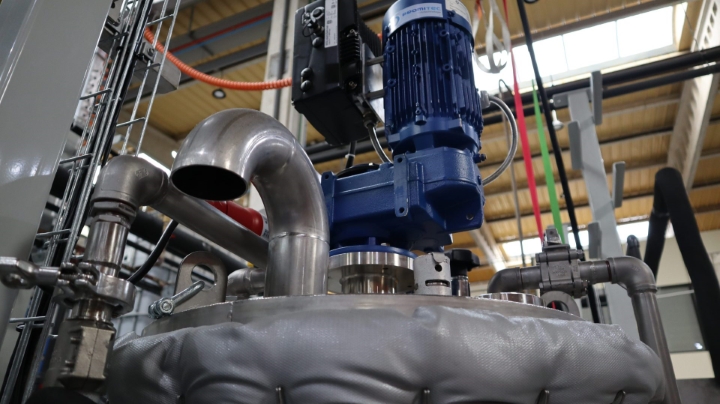

The GAIKER Technology Centre, a member of the Basque Research & Technology Alliance (BRTA), together with the Swiss company POLYMETRIX AG have developed an innovative technology and built a new pilot plant for the chemical recycling of PET waste.

The GAIKER Technology Centre, a member of the Basque Research & Technology Alliance (BRTA), together with the Swiss company POLYMETRIX AG have developed an innovative technology and built a new pilot plant for the chemical recycling of PET waste.

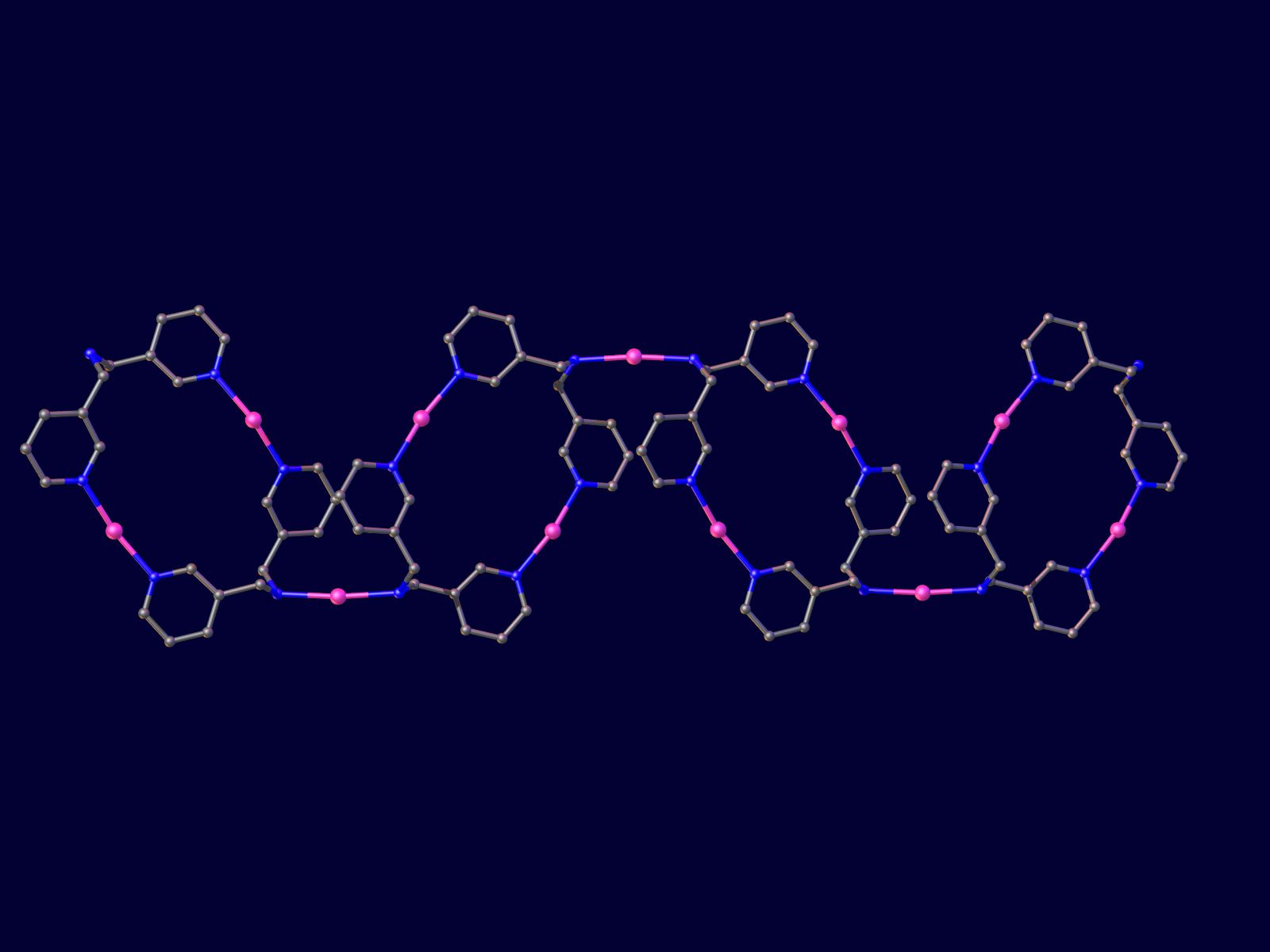

This equipment has a 150 L chemical reactor and a series of batch and continuous post-treatment and purification stages that allow it to produce high purity chemical monomers, valid for the synthesis of new PET, even food grade, and other high added value products such as PU resins, unsaturated polyester resins, paint resins, etc. Thus, it can respond to the needs of different sectors such as plastic waste recycling, petrochemicals and polymer synthesis, while promoting the circular economy.

Thanks to this plant, GAIKER can assess the suitability of complex PET waste for the production of high purity chemical monomers and define the design bases for industrial plants for the treatment of this waste. In addition, it can generate samples of the various process flows for the different stages that allow the scaling and quality parameters to be defined in each one of them.

Recycling and the Circular Economy

GAIKER is an expert in Recycling and Circular Economy. It works on the characterisation and treatment of material streams from pre- and post-consumer waste of all origins, using innovative identification and separation systems. It also develops both chemical recycling processes (pyrolysis and solvolysis), following the concepts of Plastic2Plastic, Plastic2Chemicals and Plastic2Oil&Gas to obtain monomers, chemical products, pyrolysis oils, syngas and new circular plastics, and technologies for the preparation of solid recovered fuel (SRF). It also measures and improves the sustainability of the products and processes developed through life cycle analysis tools (LCA, LCC, SLCA, LCSA) and the application of eco-design methodologies (DfX, SSbD).