New processes to give carbon and glass fibres a second life

The MC4 project, in which CIDETEC Surface Engineering participates, will establish processes to achieve 60% recyclability in these materials and strengthen Europe’s position in their value chain

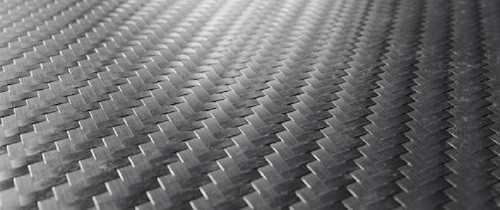

MC4 (Multi-level Circular Process Chain for Carbon and Glass Fibre Composites), a European project with the participation of CIDETEC Surface Engineering, was created with the aim of bringing circularity to carbon and glass fibre composites. During the production process of these materials, which are essential in many technical applications because they are lightweight and offer high performance, up to 40% of the product is wasted and, after a useful life of 15 to 30 years, 98% of the material is discarded with no hope of being recycled. With 110,000 tonnes of carbon fibre composite components and 4.5 million tonnes of glass fibre composites used annually, it is essential to address solutions that reduce the environmental impact they generate.

MC4 (Multi-level Circular Process Chain for Carbon and Glass Fibre Composites), a European project with the participation of CIDETEC Surface Engineering, was created with the aim of bringing circularity to carbon and glass fibre composites. During the production process of these materials, which are essential in many technical applications because they are lightweight and offer high performance, up to 40% of the product is wasted and, after a useful life of 15 to 30 years, 98% of the material is discarded with no hope of being recycled. With 110,000 tonnes of carbon fibre composite components and 4.5 million tonnes of glass fibre composites used annually, it is essential to address solutions that reduce the environmental impact they generate.

Without neglecting these environmental issues, it is necessary to improve Europe’s current competitive position in these value chains, which currently have a high degree of dependence on foreign sources. Eighty per cent of carbon and glass fibre manufacturing takes place outside Europe, while where manufacturing takes place within the EU border, the technologies often belong to foreign countries.

To offer solutions for recyclability and competitiveness, MC4 will offer research and innovation measures by:

– Establishing a multi-level circular process for carbon and glass fibre composites, with processes developed for short and long term impact on the industry.

– Developing economically realistic processes adapted to the specificities of the two value chains.

– Providing European industry with the means to master and own its own proprietary manufacturing processes for recycled materials.

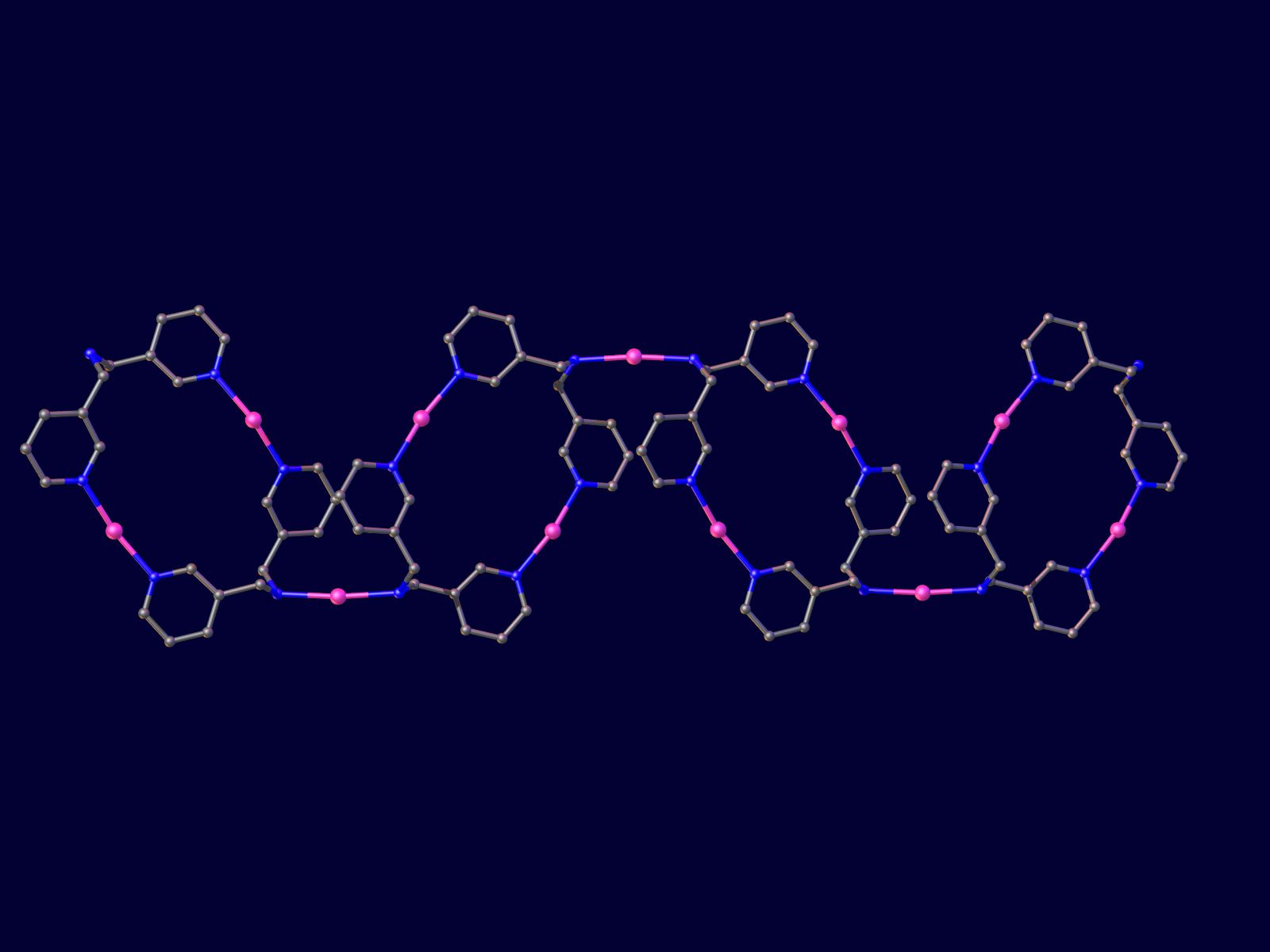

Specifically, the MC4 project will base the development of recycling processes on chemical matrix/fibre separation for carbon fibre and on a new type of resin for the direct re-use of composite material for glass fibre. As a result, and with the use of an appropriate quality classification of the recycled material, MC4 will establish processes to achieve a recycling rate of 60% and ensure the possibility to properly use the recycled materials in different applications.

To achieve its objectives, MC4 brings together 15 partners covering all links in the value chain, such as process developers, material producers or end-users manufacturing the composite parts. The pooling of skills and knowledge will enable the collaborative creation of a sustainable and viable circular process for composites. MC4 will end in March 2025.