Spectroscopic techniques and machine learning for metal waste treatment

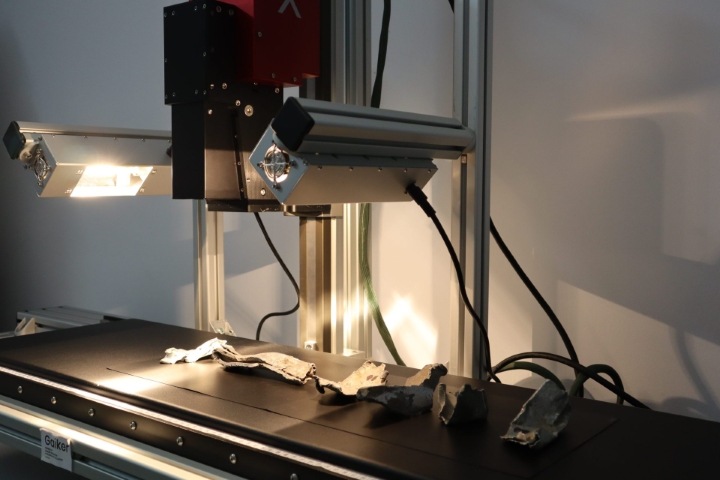

GAIKER is carrying out the IN-MET project, the aim of which is to generate a technological knowledge base that will enable progress to be made in the design and development of systems for the continuous recognition of metal alloys in waste.

The ferrous and aluminium fractions generated by waste managers do not have a homogeneous chemical composition because they are made up of a mixture of alloys that are not separated and are therefore supplied together to the foundries where they are processed. As a result, the metallurgical recovery of these metallic wastes leads to products that do not meet the requirements for certain industrial applications and are therefore destined for secondary applications. On the other hand, the non-separation of alloys can lead to the loss of alloying elements or their introduction into steel or aluminium products that do not require them.

The ferrous and aluminium fractions generated by waste managers do not have a homogeneous chemical composition because they are made up of a mixture of alloys that are not separated and are therefore supplied together to the foundries where they are processed. As a result, the metallurgical recovery of these metallic wastes leads to products that do not meet the requirements for certain industrial applications and are therefore destined for secondary applications. On the other hand, the non-separation of alloys can lead to the loss of alloying elements or their introduction into steel or aluminium products that do not require them.

In order to solve these problems, IN-MET, an industrial research project being carried out by the GAIKER Technology Centre, a member of the Basque Research & Technology Alliance, BRTA, has arisen. Its aim is to generate a technological knowledge base that allows progress in the design and development of continuous recognition systems, based on the combination of spectroscopic techniques and machine learning methods of data analysis, to classify ferrous (steel) and non-ferrous (aluminium) metals contained in metallic mixtures from waste treatment by type of alloy.

In this research, using automatic classification methods based on supervised automatic learning algorithms, the spectral fingerprints derived from scanning the metal scrap with spectroscopic techniques are analysed and the type of alloy to which they correspond is determined. Specifically, laser-induced plasma spectroscopy and hyperspectral vision are being studied in this project.

Funded by the Provincial Council of Bizkaia within the 2022 Technology Transfer Programme and co-financed by the European Regional Development Fund (ERDF), this research aims to provide the eco-industry with advanced separation solutions that enable the recovery of metal scrap of higher quality and added value thanks to its classification by type of alloy, thus contributing to the circularity of the alloying elements and the generation of a lower environmental impact in the metallurgical processes of destination.