TECNALIA presents its developments and solutions in joining and welding technologies at the UNIRE 2025 Fair

The biennial event, which is celebrating its second edition, will take place at the FICOBA exhibition centre (Irun) on 18 and 19 March, and is a benchmark forum for the exchange of knowledge and technological trends in this field

The central element of TECNALIA’s stand will be a highly versatile and automated robot-based welding cell. It is capable of automatically determining trajectories, welding parameters and closed-loop control to ensure quality

With its participation in UNIRE 2025, TECNALIA is boosting the competitiveness of industry and contributing to the major challenges of the market, such as decarbonisation, joining dissimilar materials, automation and improving efficiency and quality in production processes

On 18 and 19 March, the TECNALIA research and technological development centre will be taking part in the Welding and Joining Technologies Fair, UNIRE, where it will showcase its latest technological developments and innovative solutions in welding and material joining processes. The event, which will take place at the FICOBA venue (Irun-Gipuzkoa), is a pioneering initiative in its specific focus on joining and welding technologies. Now in its second biennial edition, it will bring together companies and professionals from the sector to promote the exchange of knowledge between the main players in this industry and to gain first-hand knowledge of their needs and market trends.

TECNALIA will showcase innovative technologies in the field of joining and welding, such as advanced robotic welding solutions, hybrid joining techniques, multi-material joining processes and real-time monitoring and control technologies. It will also present advances in characterisation techniques that improve the efficiency, durability and sustainability of joints in various industrial sectors.

Specifically, the research and technological development centre will have a stand (1/11) where it will present its experience in additive manufacturing by metal fusion using WAAM (Wire Arc Additive Manufacturing) and LMD (Laser Metal Deposition) technologies, as well as the automation of joining processes to improve efficiency and quality in manufacturing.

In addition, it will showcase its advances in high-energy beam welding, such as laser and Electron Beam Welding (EBW), for high-precision applications with highly complex materials, and its ability to perform root cause analysis (RCA) on failed welded structures and components. It will also present its solutions for the validation of welded and additively manufactured components, which ensure their performance under demanding service conditions.

The centrepiece of the stand will be a highly versatile and automated robot-based welding cell. It is capable, in a very user-friendly way, of automatically determining weld paths, welding parameters and closed-loop control of the process to ensure joint quality.

Strategic sectors

Companies attending the UNIRE fair seek to discover and update the latest innovations and advances in joining and welding technologies, establish and strengthen relationships and business opportunities with other professionals, technology centres, suppliers and companies in the sector and find technological possibilities or access to resources that allow the incorporation of young talent and generational change.

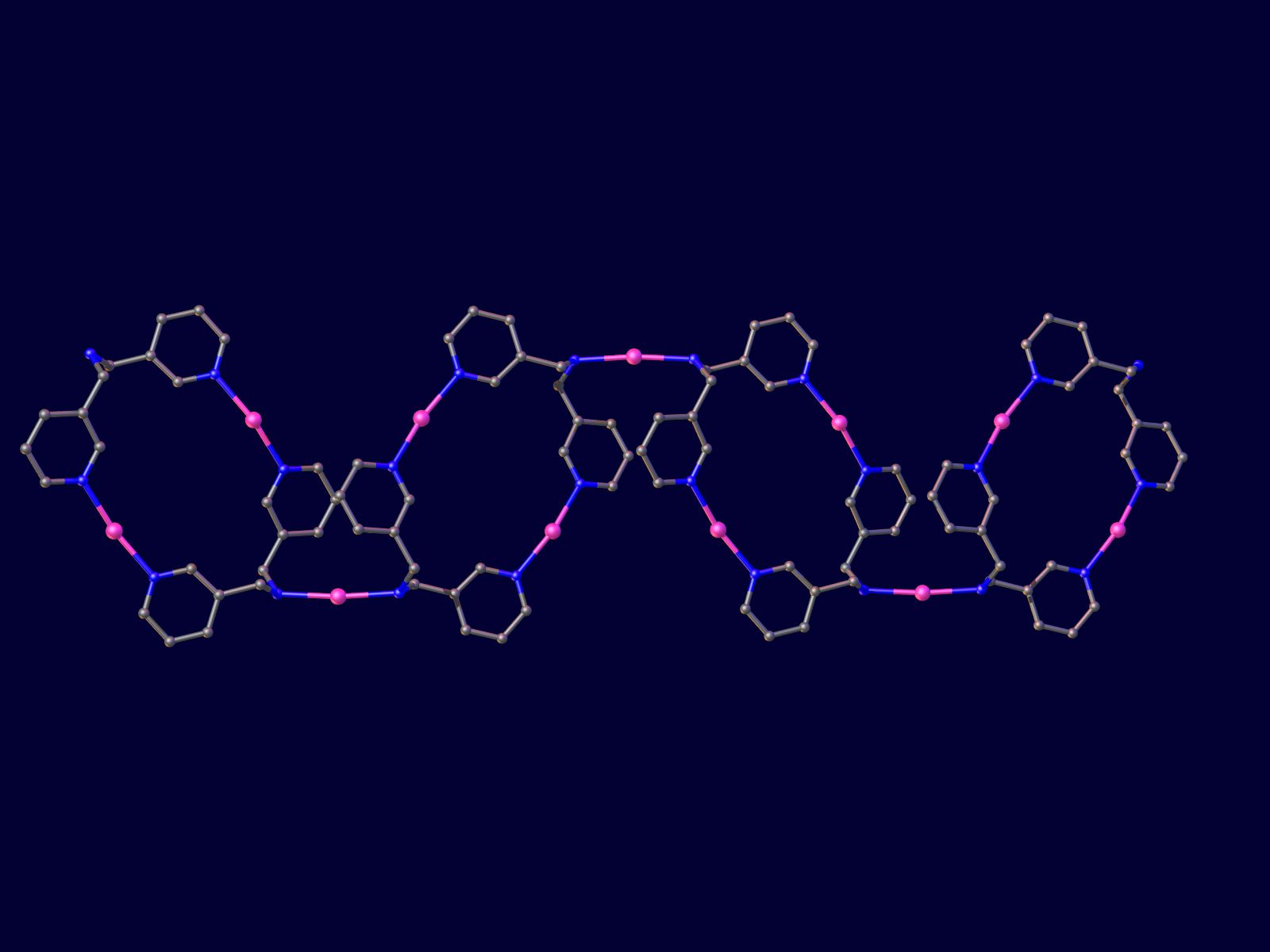

TECNALIA works in the development and manufacture of joints for sectors with high technical requirements, such as nuclear fusion, particle accelerators, wind energy, automotive, aeronautics, naval and aerospace. In this context, it researches and develops technologies such as friction stir welding (FSW) for dissimilar materials and manual arc welding for specialised applications.

The technology centre also offers advanced solutions to optimise welding and joining processes, including feasibility studies for joining dissimilar materials, prototyping with advanced technologies and joining of unconventional and high-value materials such as superalloys, copper and ceramics.

With its participation in UNIRE 2025, TECNALIA boosts the competitiveness of the industry and contributes to the major challenges of the market, such as decarbonisation, joining dissimilar materials, automation and improving efficiency and quality in production processes.