Lantek strengthens its international expansion with Machitech, a Canadian manufacturer of high-power cutting systems

Lantek, a global provider of software solutions for the metal industry, has reached a collaboration agreement with Machitech, a Canadian manufacturer specialising in high-performance laser, plasma and oxyfuel cutting systems, to integrate Lantek software solutions into its machines.

The alliance represents another step forward in Lantek’s international growth strategy and strengthens its collaboration with leading technology manufacturers in North America and Europe. Under this agreement, Machitech’s Fiber PRIME S™ laser cutting machines will incorporate Lantek Expert Cut, while its Fiber TUBE XL™ tube cutting equipment will integrate Lantek Flex3D Tubes.

Canadian technology with a clear industrial focus

Based in Quebec, Machitech is renowned for developing custom-configured machines, particularly in high-power plasma and oxyfuel cutting technologies, a technical segment with demanding industrial requirements that is less common in today’s market. In recent years, the company has expanded its catalogue to include steelwork, structural profiles and tube applications, consolidating its offering aimed at manufacturers with complex, high added-value production processes.

The Fiber PRIME S series covers power ratings between 12 and 60 kW and incorporates bevelling capabilities for machining thick steel. Its XL version allows working with long parts and is equipped with touch control and remote management systems, designed for demanding production environments.

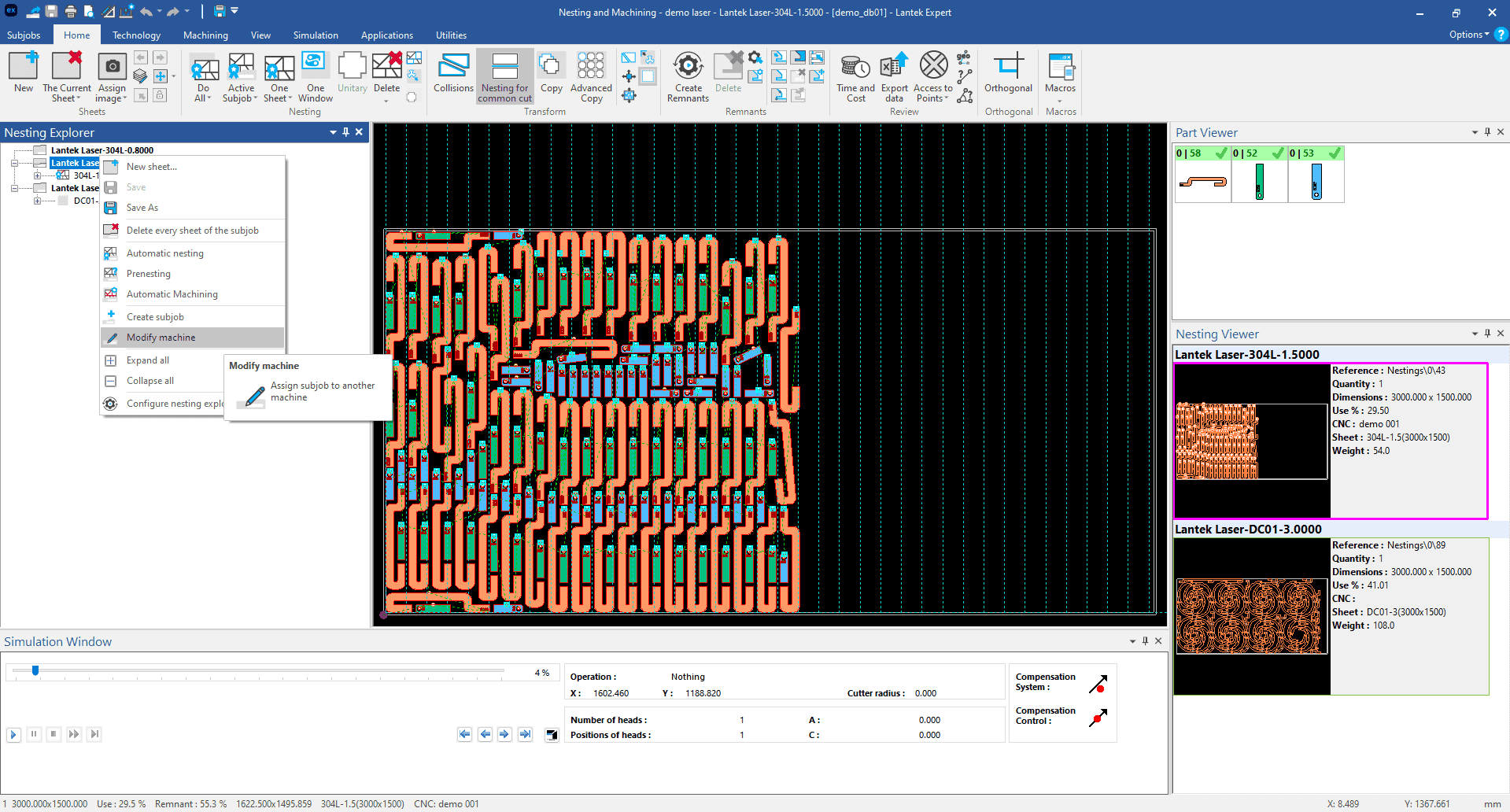

In this context, Machitech has opted to integrate specialised CAD/CAM software that allows the machine to be used to its full potential from day one. Lantek Expert Cut provides advanced 2D nesting functions, cutting path generation and direct management of 3D geometries using the Assembly 2 Nest (A2N) importer, all within a single working environment.

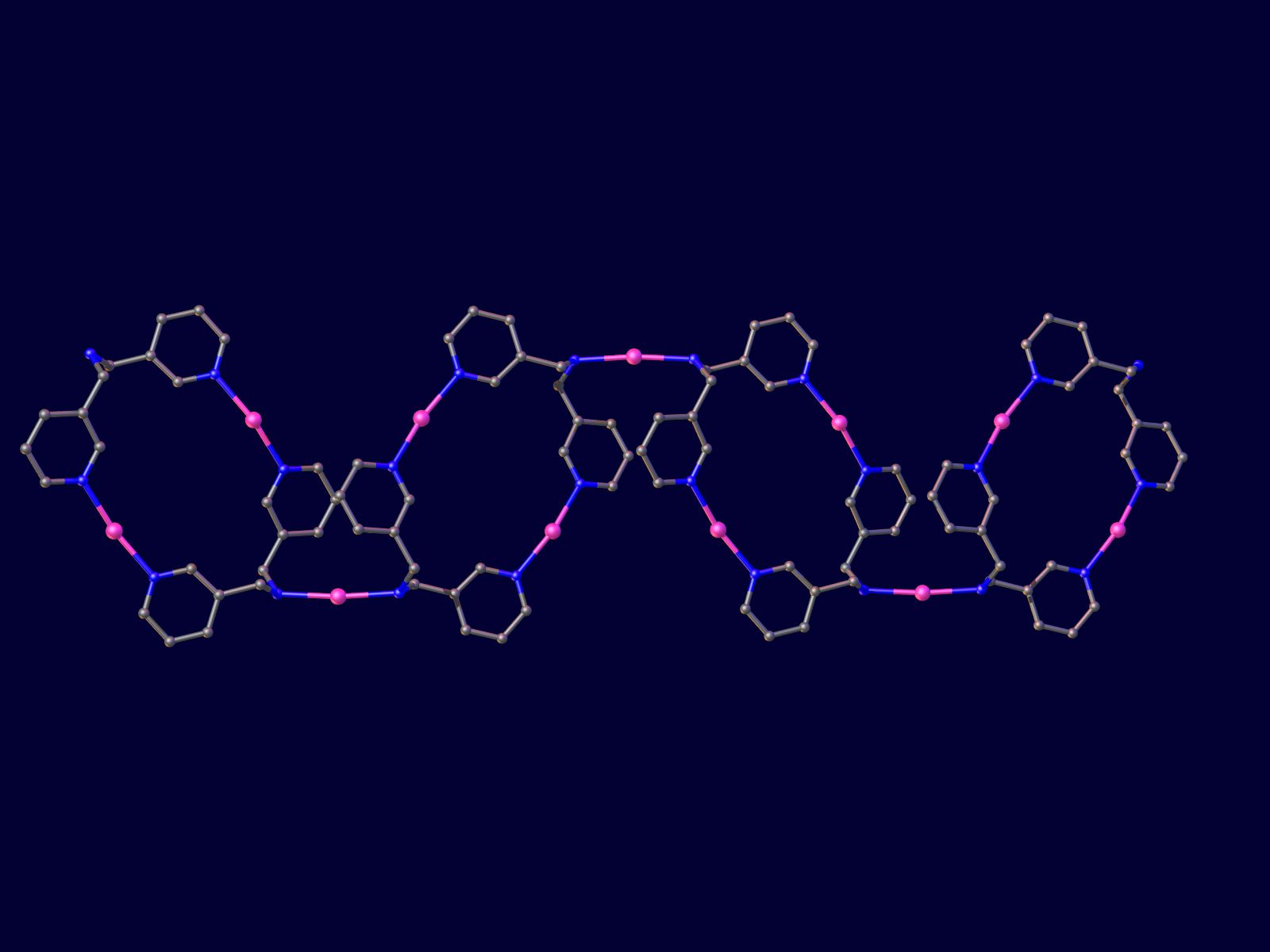

For tube cutting, the Fiber TUBE XL machine incorporates Lantek Flex3D Tubes, a solution developed for machining large-diameter tubes and profiles. The system allows working with round and square tubes, HSS profiles and small beams, with lengths of up to 12 metres.

The software enables the design, nesting and machining of parts directly on the tube, as well as the import of SAT and IGES files. Pre-simulation of the process and real-time parameter modification reduce risks, improve cutting quality and protect critical machine components.